Minimize waste & reduce environmental impact

In our daily operations, we focus on practices that help reduce environmental impact, both in collaboration with our employees, clients and suppliers. We maintain a zero-waste policy by reducing, reusing, and recycling our production materials, minimizing waste generation and protecting the environment. We invest in energy efficiency projects and solutions to reduce our carbon footprint.

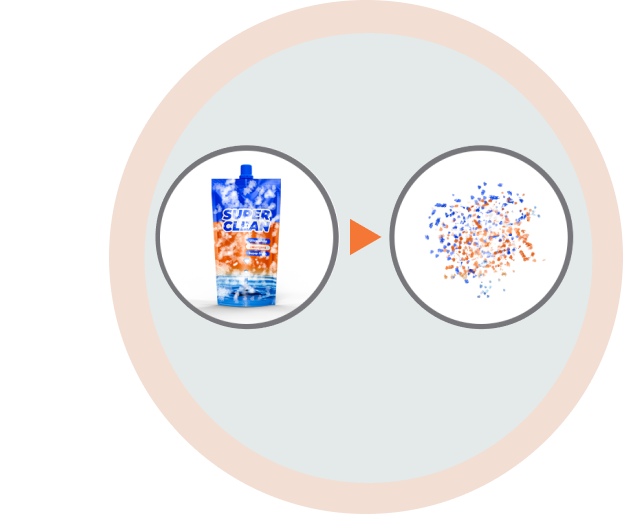

Usage of a new range of bioplastic raw materials that are 100 % compostable and degradable.

The acquisition of state-of-the-art machinery has resulted in high energy efficient processes, reducing our carbon footprint.

Our paper coated film degrades naturally by microbial action in conventional landfills, avoiding the need for composting facilities.

Superb sealing and high gas barrier characteristics to produce hermetically sealed packages, avoiding product spoilage and waste, and substituting non-recyclable structures such as aluminum foil.

Selecting and developing the cleanest energy available in the sites we operate such as hydraulic, solar and cogeneration.

Scrap generated during the manufacturing process is either collected and regranulated or sold for other applications.

We reuse leftover aluminum wires that were used in the metallization process.

We collect packaging materials such as wooden pallets and boards from our clients, in order to recover and reuse them in our secondary packaging process.

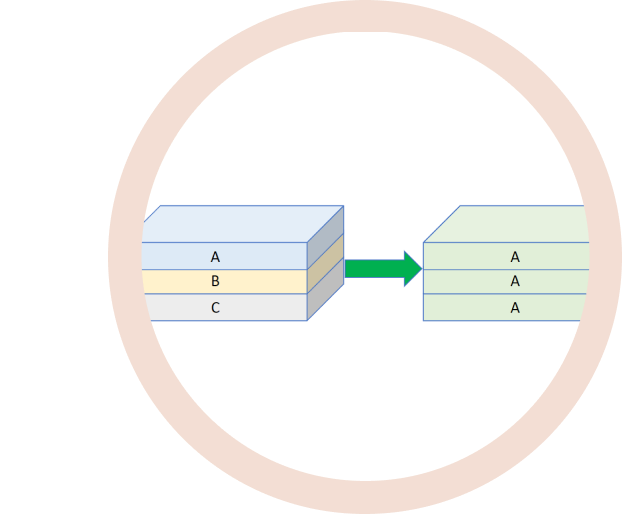

Design and development of mono-material structures that contribute to correct collection for recycling.

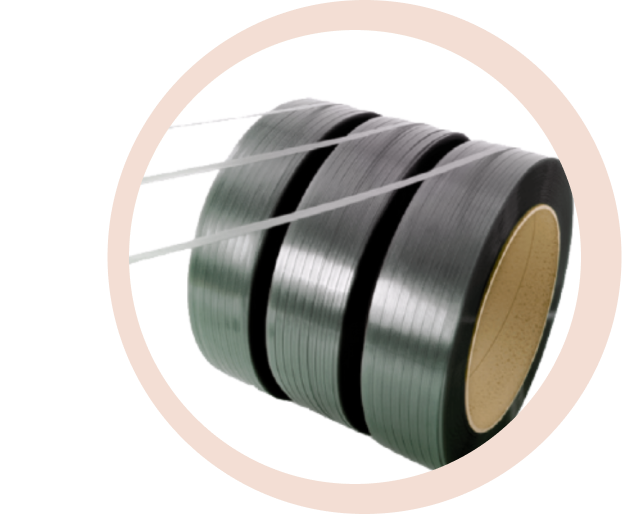

PET scrap is being converted into industrial straps, made out of 100% post-industrial recycled virgin content.

PA scrap is converted into engineering resins and used in different components in the automotive and general industry and consumer appliances.